STOCKHOLM, SE / ACCESS Newswire / February 18, 2026 / Stockholm Precision Tools (SPT) has successfully completed the first field deployment of its SPT GyroTracer GWD (Gyro While Drilling) system in Nigeria, marking a significant milestone for gyro-based wellbore positioning in magnetically challenging drilling environments.

GWD (Gyro While Drilling) system in Nigeria, marking a significant milestone for gyro-based wellbore positioning in magnetically challenging drilling environments.

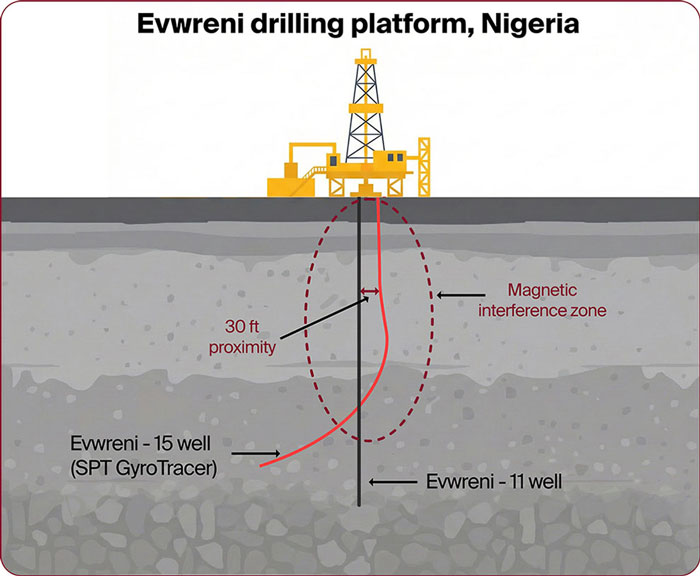

The operation was executed by Segofs Energy Services Limited on the Evwreni-15 well, where tight well spacing and magnetic interference rendered conventional magnetic MWD solutions unreliable. Results from the deployment indicate measurable gains in operational efficiency, positioning confidence, and cost avoidance, key priorities for drilling and directional teams working in mature or congested fields.

Drilling operations on the Evwreni platform during the GyroTracer GWD deployment.

GWD deployment.

Addressing Magnetic Interference in Tight Well Spacing

The Evwreni-15 well presented a high-risk collision scenario, with anti-collision analysis showing a minimum separation of approximately 30 ft from the adjacent Evwreni-11 well. The presence of steel casing and an East-West trajectory, well known for degrading magnetic sensor accuracy, made standard MWD-based directional surveying unsuitable for the operation.

To mitigate collision risk and maintain precise wellbore placement, Segofs selected the SPT GyroTracer GWD, which relies on a high-accuracy north-seeking gyroscope rather than the Earth's magnetic field. This magnetic-field-independent approach enables consistent and reliable directional data, even in close proximity to casing, conductors, or other sources of magnetic distortion.

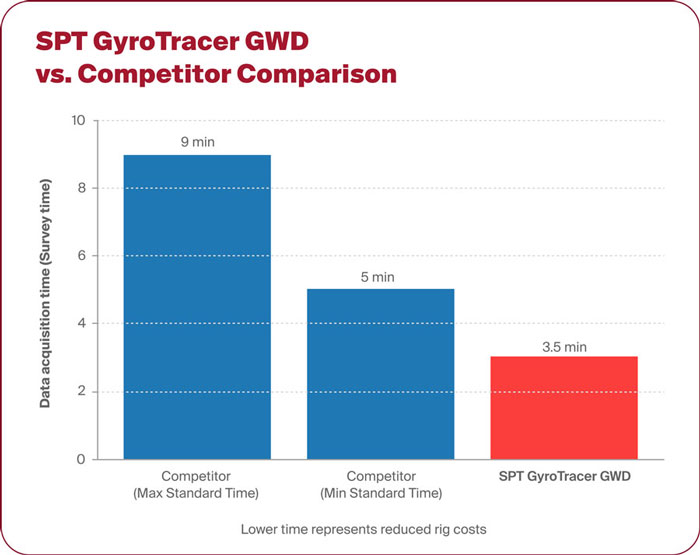

Faster Surveys, Zero Re-runs, and Tangible Cost Savings

One of the most notable outcomes of the deployment was the reduction in survey time and associated non-productive time. While competing gyro systems typically require 5-9 minutes per survey in the region, the GyroTracer GWD consistently completed full measurements in under 3.5 minutes.

According to the operator, this performance delivered several operational benefits:

At least 12 hours of rig timesaved, translating to approximately USD 60,000 in avoided rig spread costs

Elimination of drop-gyro runs over the first 2,000 ft of drilling

Zero non-productive time (NPT) related to gyro surveys, with no survey re-runs required

Bart Nwibe, Managing Director of Segofs Energy, emphasized the operational value: "No time was spent 'waiting on survey,' as survey data became available immediately once flow was initiated after the connection, eliminating drilling delays and ensuring uninterrupted operations."

The system also proved critical during a trajectory nudge at 600 ft, where accurate, magnetically independent data enabled confident directional control despite interference from a 24-in. conductor.

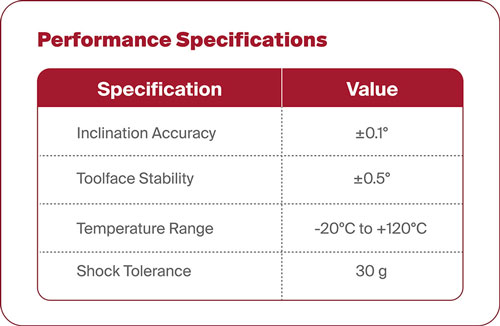

Design and Intelligent Data Quality Control

The GyroTracer GWD is designed for seamless integration with Tensor-based MWD systems and

EclipseTouch software, allowing flexible placement anywhere in the bottomhole assembly. The tool operates using multiple intelligent modes that balance power consumption with measurement precision.

Advanced onboard processing filters environmental noise and disturbances to deliver high-quality survey data under demanding downhole conditions. Each survey is automatically accompanied by a real-time quality control (QC) assessment, allowing drilling and directional teams to immediately verify data reliability and determine whether a repeat measurement is required-reducing uncertainty and preventing unnecessary delays.

Field Integration and 24/7 Technical Support

Field crews described the system integration as "impeccable." Using a shared communication unit for both the GWD and MWD hardware simplified real-time data access for both rig-site personnel and remote operations teams. SPT also provided 24/7 technical support throughout the operation, resolving post-job data formatting challenges without impacting drilling progress.

Adoption for Upcoming Wells

Following the successful performance on Evwreni-15, the operator has formally approved the GyroTracer GWD for use on three additional wells planned on the same platform. The deployment reinforces the viability of gyro-based GWD technology for collision avoidance and directional control in Nigeria's increasingly congested drilling environments, while further positioning Segofs Energy Services as a leading provider of high-precision directional drilling services in the region.

About

Stockholm Precision Tools (SPT)

With decades of experience, SPT is a global leader in the design and manufacture of high-precision gyroscopic surveying instruments for the mining, civil engineering, and oil and gas industries.

Segofs Energy Services Limited

Segofs Energy Services Limited is Nigeria's leading directional drilling services company, focused on deploying advanced technologies to improve drilling performance, safety, and operational efficiency.

Media Contact:

Eric Estrada

Global Marketing Director

Stockholm Precision Tools (SPT)

[email protected]

www.sptab.com

SOURCE: Stockholm Precision Tools AB

Related Documents:

- drilling-platform - en

- drilling-platform - es

- GWD competitor time comparison - es

- GWD competitor time comparison - en

- GWD performance specifications - en

- GWD performance specifications - es

View the original press release on ACCESS Newswire